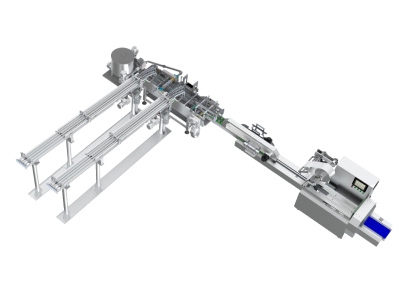

The food industry demands precision, speed, and hygiene in packaging—especially for fragile products like biscuits. A biscuit packaging machine ensures your products are wrapped securely, whether through on edge packaging for stability or a horizontal flow pack machine for versatility. These systems enhance shelf appeal, reduce waste, and comply with international safety standards.

1. Why Choose a Biscuit Packaging Machine?

Modern biscuit packaging machines automate the wrapping process, offering:

- High-speed performance (up to 200 packs/minute).

- Gentle handling to prevent breakage.

- Customizable packaging (flow packs, boxes, or trays).

- Food-grade materials for compliance with FDA/CE standards.

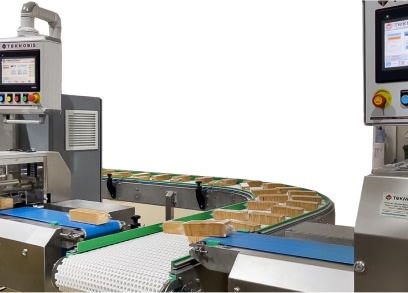

2. On Edge Packaging: Perfect for Delicate Biscuits

On edge packaging positions biscuits vertically, minimizing movement during transit. Benefits include:

- Reduced product damage during shipping.

- Efficient space utilization in cartons.

- Enhanced visual appeal on retail shelves.

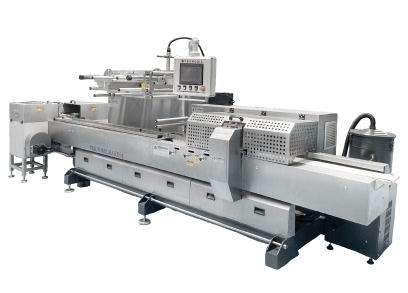

3. Horizontal Flow Pack Machine: Versatility & Speed

A horizontal flow pack machine wraps biscuits in airtight films, extending freshness. Key features:

- Adjustable sealing temperatures for varied materials.

- Multi-language HMI for easy operation.

- Integration with conveyors for seamless production lines.

4. Technical Specifications & Customization

Our biscuit packaging machines support:

- Multiple biscuit sizes (from crackers to sandwich types).

- MOQ-friendly solutions for SMEs and large manufacturers.

- Energy-saving modes to cut operational costs.

5. Applications Across Industries

Beyond biscuits, these machines package:

- Snacks, chocolates, and granola bars (via horizontal flow pack).

- Pharmaceuticals (using on edge packaging for blister packs).

- Cosmetics for tamper-proof sealing.