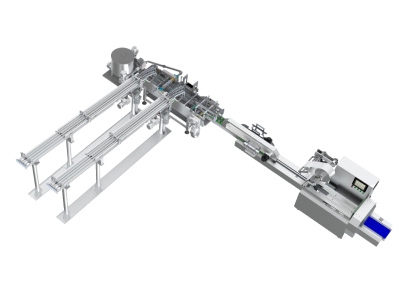

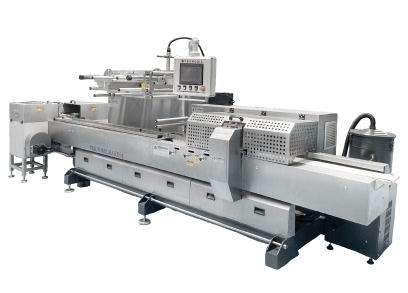

Flow Wrapper: Precision Horizontal Packaging for Biscuits

(Form-Fill-Seal Technology)

Key Specifications

| Parameter | Specification |

|---|---|

| Speed | Up to 600 packs/min |

| Package Width | 50-300mm (adjustable) |

| Film Types | OPP/PE, PET/PE, Biodegradable |

| Sealing Type | Constant-temperature or pulsed sealing |

| Power | 5.5kW, 380V 3-phase |

Core Features

- Advanced Film Control System

- Servo-driven film tension control (±0.5N)

- Automatic splicing for uninterrupted production

- 98% material utilization efficiency

- Intelligent Sealing Technology

- PID-controlled heating zones (±1°C accuracy)

- Dual verification:

∙ Thermal camera for seal integrity

∙ Pressure sensor for seal consistency

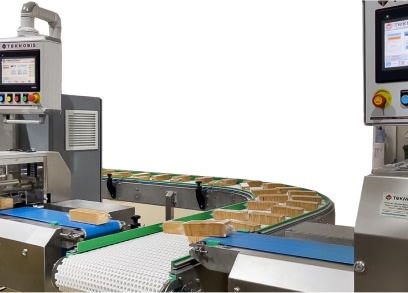

- Quick Changeover

- Tool-less adjustment (<3 minutes)

- Memory for 50+ product recipes

- Automatic film width detection

Industry 4.0 Integration

- OPC UA interface for MES/ERP connectivity

- Predictive maintenance with vibration sensors

- Real-time KPI monitoring (OEE, downtime tracking)

Biscuit-Specific Advantages

- Gentle product handling with soft-drop loading

- Anti-crumb vacuum system

- Moisture control option for crispness retention

Options Available:

- Nitrogen flushing (MAP) for extended shelf life

- Inkjet printing integration

- X-ray inspection system

Certifications: CE, UL, ISO 22000, FDA-compliant

Service Package:

- Remote diagnostics via AR glasses

- On-site training program

- 24/7 technical support hotline

Why This Flow Wrapper?

◉ 30% Higher Output vs. conventional models

◉ <0.5% Reject Rate with AI quality control

◉ Energy Saving – 15% lower power consumption

Request a Live Demo – See how it handles your specific biscuit products!

This version:

✅ Targets engineering and procurement professionals

✅ Combines technical depth with commercial appeal

✅ Uses measurable performance claims

✅ Structured for quick scanning

✅ Includes unique selling propositions