Definition & Process:

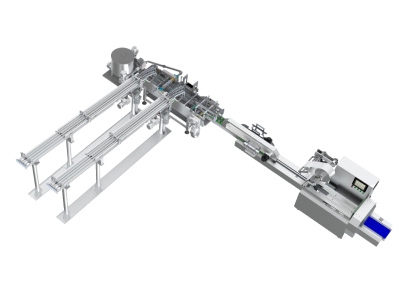

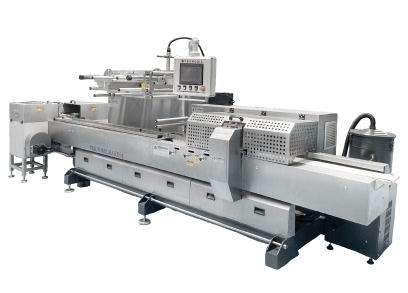

Flow wrap packaging (horizontal form-fill-seal) is an automated method where products are wrapped in flexible films with precision end seals. The process involves film forming, product insertion, longitudinal sealing, end sealing, and cutting.

Key Technical Specifications:

- Machine Components:

- Film unwinding system with tension control

- Forming collar/shoulder (adjustable angles)

- Longitudinal sealing system (constant temperature)

- Cross sealing jaws (servo-controlled)

- Precision cutting mechanism

- Performance Parameters:

- Speed range: 50-800 packages/minute

- Film width handling: 150-650mm

- Product length capacity: 30-500mm

- Package thickness: 5-150mm

- Power requirement: 3-10kW (380V)

- Material Compatibility:

- Films: BOPP, PET, PE, metallized, laminated

- Thickness range: 15-80μm

- Printability: Up to 10-color flexo printing

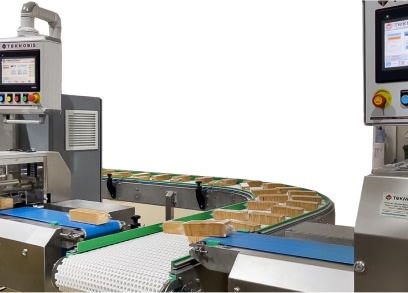

Quality Control Systems:

- Integrated checkweigher (±0.5g accuracy)

- Metal detection (Fe 0.3mm, Non-Fe 0.5mm)

- Vision inspection (200fps camera speed)

- Automatic rejection systems

Advanced Features:

- Quick changeover system (<5 minutes)

- Nitrogen flushing capability (for MAP)

- IoT-enabled performance monitoring

- Predictive maintenance alerts

- Energy-saving mode (up to 30% reduction)

Industry Applications:

- Food:

- Bakery products

- Confectionery

- Snack foods

- Frozen goods

- Non-Food:

- Pharmaceuticals

- Medical devices

- Hardware items

- Stationery products

Cost Structure:

- Entry-level: $50,000-$100,000

- Mid-range: $100,000-$250,000

- High-performance: $250,000-$500,000+

Maintenance Protocol:

- Daily:

- Seal jaw cleaning

- Film path inspection

- Weekly:

- Chain lubrication

- Sensor calibration

- Monthly:

- Servo motor checks

- Mechanical alignment

Technical Advantages:

- Higher packaging speeds vs vertical systems

- Better material utilization (5-15% savings)

- Superior package integrity

- Flexible format changes

- Lower operational costs

Regulatory Compliance:

- CE Marking

- FDA 21 CFR Part 11

- EHEDG certification

- ISO 9001:2015

For optimal machine selection, please provide:

- Product dimensions

- Required output

- Packaging material specifications

- Special requirements (MAP, printing, etc.)