The price of a flow wrap machine can vary widely depending on several important factors, including the machine’s size, speed, automation level, and the specific features it offers. Flow wrap machines are widely used in various industries to package products such as food items, pharmaceuticals, and consumer goods efficiently and securely.

Basic, entry-level flow wrap machines designed for small-scale operations or startups generally come with a more affordable price tag. These models typically feature manual or semi-automatic operation and lower packaging speeds, making them suitable for businesses with moderate production volumes.

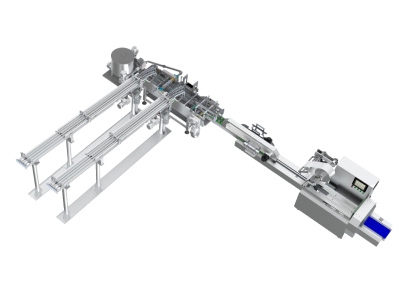

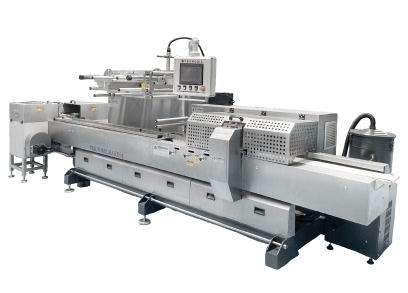

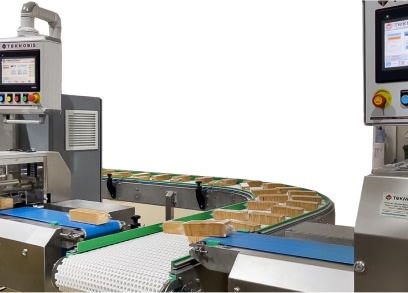

On the other hand, fully automatic, high-speed flow wrap machines equipped with advanced technologies—such as integrated weighing systems, product feeding conveyors, and precise sealing mechanisms—command a higher investment. These machines are designed to handle large production capacities with minimal downtime, offering enhanced reliability and versatility.

Additional factors influencing the price include the type of packaging materials compatible with the machine (such as plastic films, laminates, or biodegradable wraps), the complexity of the control interface, and any customization or brand-specific requirements.

It is essential for businesses to carefully assess their production needs and budget constraints before purchasing a flow wrap machine. Consulting with manufacturers or suppliers to obtain detailed quotations and understand after-sales support options can help ensure that the investment aligns with long-term operational goals.

Ultimately, while the initial cost of a flow wrap machine may seem significant, the efficiency gains, product protection, and packaging quality it delivers often lead to substantial cost savings and improved customer satisfaction over time.