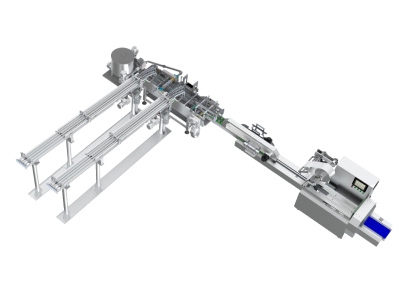

A flow pack packaging machine is a widely used automatic or semi-automatic device designed to package products horizontally in a continuous film. This type of packaging is also known as horizontal flow wrapping and is ideal for high-speed, efficient packaging of a variety of products.

What is a Flow Pack Packaging Machine?

A flow pack machine wraps products in a continuous roll of flexible film (plastic or laminated), forming a sealed pouch or sleeve around the product. The film moves horizontally, enclosing the product and sealing the ends to create individual packages.

The machine handles feeding, wrapping, sealing, and cutting in one integrated system. Flow pack machines are popular across food, pharmaceutical, cosmetic, and industrial sectors due to their speed, reliability, and versatility.

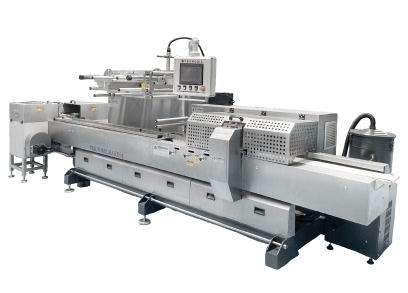

How Does a Flow Pack Machine Work?

The packaging process involves several steps:

- Product Feeding: Products can be loaded manually or automatically via conveyor belts or feeders.

- Film Unwinding: A roll of packaging film is placed on the machine and unwound smoothly.

- Film Formation: The film is shaped into a tube or sleeve around the product by a forming collar.

- Product Enclosure: The product passes through the film sleeve.

- Sealing: The machine performs a continuous longitudinal seal along the film length and intermittent transverse seals at intervals to form individual sealed packages.

- Cutting: The sealed package is cut from the continuous film and discharged.

Types of Flow Pack Machines

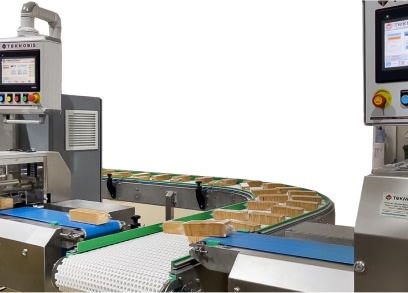

- Horizontal Flow Pack Machines: The most common type, wrapping products horizontally with film moving side to side.

- Vertical Flow Pack Machines: Used for products fed vertically into packaging, common in powder or granular goods.

- Tabletop Flow Wrap Machines: Compact versions designed for smaller production volumes or limited space.

- High-Speed Industrial Flow Pack Machines: For large-scale manufacturing with very high packaging speeds.

Common Packaging Materials

Flow pack machines can handle various films depending on the product requirements:

- BOPP (Biaxially Oriented Polypropylene): Offers good clarity, strength, and printability.

- CPP (Cast Polypropylene): Flexible, heat sealable, and moisture resistant.

- PE (Polyethylene): Good moisture barrier and flexibility.

- Laminated Films: Multi-layer films combining properties like oxygen barrier, moisture resistance, and print quality.

- Biodegradable/Bio-based Films: Emerging eco-friendly options.

Advantages of Flow Pack Packaging

- Product Protection: Seals the product from contamination, moisture, and physical damage.

- Attractive Presentation: Clear films allow product visibility; customizable printing adds branding.

- High Speed & Efficiency: Machines can package tens to hundreds of products per minute.

- Versatility: Can package a wide variety of product shapes and sizes.

- Reduced Waste: Precise film use reduces material waste compared to rigid packaging.

- Cost-Effective: Compared to rigid boxes or trays, flow packs often reduce packaging costs.

Typical Applications

- Food Industry: Snack bars, biscuits, chocolates, bakery items, confectionery, fresh produce.

- Pharmaceuticals: Medical devices, blister packs, sachets.

- Cosmetics: Small bottles, bars of soap, makeup accessories.

- Hardware and Electronics: Small parts, accessories, tools.

Considerations When Choosing a Flow Pack Machine

- Product Size and Shape: Some machines handle irregular shapes better than others.

- Production Volume: Speed and capacity requirements impact machine choice.

- Film Compatibility: Confirm the types of films the machine can handle.

- Automation Level: Manual feeding vs. fully automated lines.

- Space Available: Compact vs. industrial floor models.

- Budget: Balancing cost, features, and maintenance needs.

Maintenance and Safety Tips

- Regular cleaning of sealing jaws and film paths to avoid jams.

- Checking and replacing cutting blades and sealing elements as needed.

- Following manufacturer safety guidelines for guards and operation.

- Routine calibration for consistent sealing quality.

Leading Manufacturers

Some well-known brands in the flow pack packaging machine market include:

- Bosch Packaging Technology

- ULMA Packaging

- Multivac

- Ishida

- Hayssen Flexible Systems

Conclusion

Flow pack packaging machines offer a flexible, fast, and cost-effective packaging solution for a wide range of industries. Their ability to deliver secure, attractive packaging while maximizing production efficiency makes them an essential investment for many manufacturers.

If you want, I can help you select the right machine model based on your product type, volume, and budget!