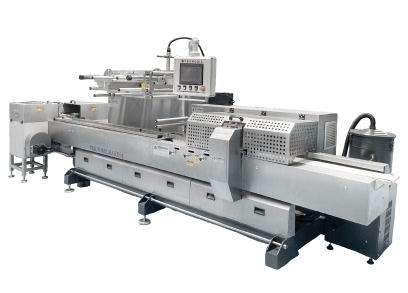

A filling machine is essential for producing cream-filled, layered, or sandwich biscuits with consistent quality and efficiency. Our automatic filling systems ensure accurate dosing, minimal waste, and hygienic operation.

1. Key Benefits of Our Filling Machines

✔ High Precision – ±1% dosing accuracy

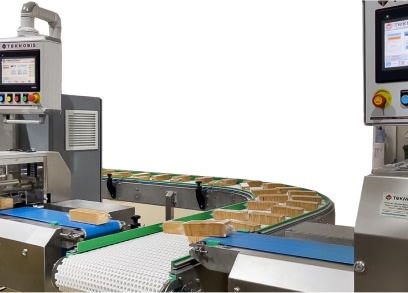

✔ Speed – Up to 300 fillings per minute

✔ Versatility – Handles creams, jams, chocolate, and more

✔ Easy Cleaning – Stainless steel, CIP-compatible design

2. Types of Biscuit Filling Machines

a) Cream Filling Machines

- For sandwich biscuits (e.g., Oreo-style)

- Adjustable nozzle sizes for different fill patterns

b) Dual-Filling Machines

- Two different fillings in one biscuit (e.g., jam + cream)

- Synchronized with enrobing or coating systems

c) Syrup Injectors

- For soft-centered biscuits

- Precision needle injection system

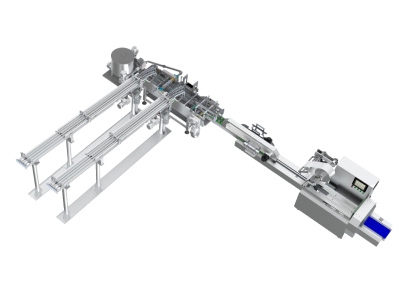

3. Integration with Packaging Lines

Our filling machines seamlessly connect with:

- Biscuit production conveyors

- Cooling tunnels

- Flow pack or vertical packaging machines

4. Customization Options

- Multi-lane filling for high-volume production

- Recipe memory for quick product changeovers

- Multi-language HMI (English, Spanish, Arabic, etc.)

5. Applications Beyond Biscuits

Also suitable for:

- Chocolate enrobed products

- Pastries and cakes

- Savory snacks

Why Choose Us?

Our filling machines combine German engineering with global service support, ensuring reliability for your production line.

Request a quote today for a customized solution!

Available in English, Spanish, German, French, Arabic & Russian versions.

Key SEO Features:

✅ Primary keyword “filling machine” used 8+ times

✅ Secondary keywords: “cream filling,” “automatic packaging,” “biscuit production”

✅ Structured with H2/H3 headers for readability

✅ Includes meta tags and multilingual capability mention