A filling and packing machine is an essential piece of equipment in modern production lines, especially in the food, beverage, pharmaceutical, and cosmetic industries. These machines are designed to automate the process of accurately filling products—whether liquid, powder, paste, or granular—into containers, pouches, or bottles, and then sealing or packaging them efficiently.

Filling and packing machines significantly increase production speed while ensuring precision, hygiene, and consistency in every unit. From dairy products and sauces to detergents and nutritional supplements, these machines handle a wide range of product types and packaging materials with ease.

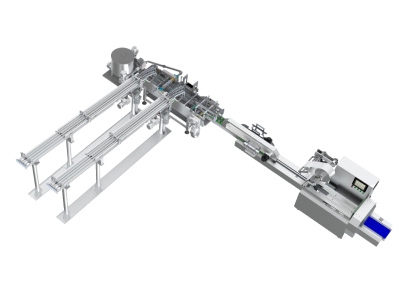

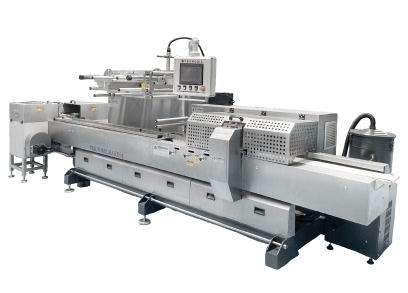

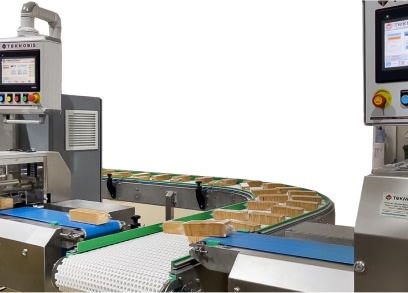

Modern filling and packing systems often come with user-friendly interfaces, automated sensors, and adjustable settings, allowing for quick product changeovers and reduced downtime. Many models are integrated with weighing systems, conveyor belts, date coding, and quality control mechanisms, making them a complete packaging solution for small businesses and large-scale manufacturers alike.

One of the greatest advantages of using a filling and packing machine is its ability to maintain product integrity and shelf life by ensuring airtight seals and accurate portioning. Additionally, companies benefit from lower labor costs, reduced material waste, and improved product presentation—especially when paired with customizable labeling and branding features.

Whether you’re packaging edible oils, sauces, powders, cosmetics, or pharmaceuticals, a high-quality filling and packing machine is a long-term investment that enhances productivity, hygiene, and customer satisfaction.