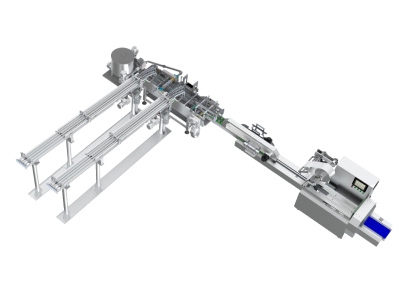

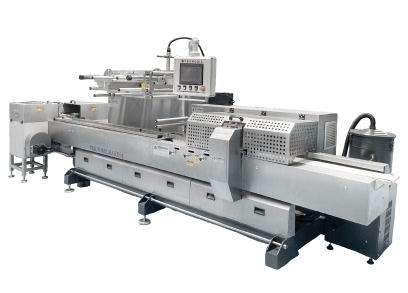

A horizontal flow packing machine is a type of automated or semi-automated equipment designed to package products by wrapping them horizontally in a flexible film. This packaging method is commonly known as horizontal flow wrapping or flow pack packaging, and it is widely used in industries for its speed, efficiency, and versatility.

What is a Horizontal Flow Packing Machine?

A horizontal flow packing machine wraps products in a continuous roll of flexible film, forming a sleeve or pouch around the product. The film is sealed along the length and then sealed and cut transversely to create individual, hermetically sealed packages.

The machine combines several functions in one continuous process: product feeding, film unwinding, film forming, sealing, and cutting. This machine is especially suited for packaging products that are relatively small to medium-sized and require quick, consistent packaging.

How Does It Work?

The packaging process includes these key steps:

- Product Feeding: Products are placed onto the machine’s conveyor either manually or via automated feeders.

- Film Unwinding: The packaging film, usually plastic or laminated, is unwound from a roll.

- Film Forming: The film is shaped into a tube or sleeve around the product by a forming collar.

- Wrapping: The product passes through the formed film sleeve.

- Longitudinal Sealing: The film is sealed along its length to enclose the product inside the sleeve.

- Transverse Sealing and Cutting: The ends of the package are sealed crosswise and cut to separate individual packages.

Types of Films Used

Common packaging films used in horizontal flow packing machines include:

- BOPP (Biaxially Oriented Polypropylene): Transparent, strong, and printable.

- CPP (Cast Polypropylene): Flexible and heat-sealable.

- PE (Polyethylene): Provides moisture barrier and flexibility.

- Laminated Films: Multi-layered films offering barrier properties for oxygen, moisture, and light.

- Biodegradable Films: Eco-friendly options growing in popularity.

Advantages of Horizontal Flow Packing Machines

- High Speed and Efficiency: Capable of packaging dozens to hundreds of products per minute depending on the model.

- Versatility: Suitable for a wide range of product sizes and shapes.

- Product Protection: Provides hermetic sealing that protects against dust, moisture, and contamination.

- Enhanced Product Presentation: Transparent films allow product visibility; printed films support branding.

- Material Optimization: Less material waste compared to rigid packaging solutions.

- Cost-Effectiveness: Reduced packaging costs per unit.

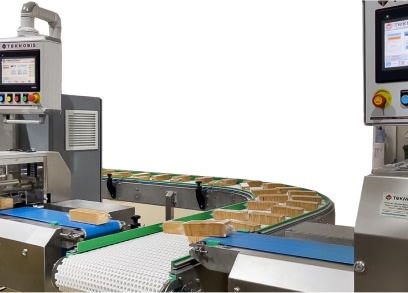

- Integration: Easily integrated into automated production lines.

Common Applications

Horizontal flow packing machines are widely used across sectors, including:

- Food Industry: Snacks, biscuits, chocolate bars, bakery products.

- Pharmaceuticals: Medical devices, tablets, blister packs.

- Cosmetics: Soap bars, small cosmetic accessories.

- Industrial: Small hardware components, spare parts.

Key Considerations When Choosing a Machine

- Product Size and Shape: To ensure compatibility with the machine’s feeding and wrapping system.

- Production Volume: To select a machine with adequate speed and capacity.

- Film Type: Compatibility with specific packaging films.

- Level of Automation: Manual, semi-automatic, or fully automatic product feeding.

- Available Space: Machine footprint must fit in the production area.

- Budget: Balancing cost, features, and maintenance.

Maintenance and Safety Tips

- Regular cleaning of sealing jaws and film paths to prevent jams.

- Routine inspection and replacement of sealing and cutting components.

- Compliance with safety standards to protect operators.

- Proper training for machine operators to ensure safe and efficient operation.

Leading Manufacturers

Some top manufacturers of horizontal flow packing machines include:

- Bosch Packaging Technology

- ULMA Packaging

- Multivac

- Ishida

- Hayssen Flexible Systems

Conclusion

Horizontal flow packing machines are an excellent solution for companies looking for fast, reliable, and attractive packaging of products in flexible films. Their ability to handle various product types and volumes makes them a vital part of modern packaging lines.

If you want, I can help you select the right model for your needs or provide a comparison of available machines.